Elastomeric bearings normally consist of a number of rubber layers separated by steel plates normally molded in pads or strips and are ideally suited for small structures to accommodate movements by deformation shear and rotations. Elastomeric bearings provide an excellent economic solution for applications where structure movements, longitudinal, transverse and rotational are small, provide vibration isolation and are generally simple to install. Neoprene rubber laminated Elastomeric bearings are relatively maintenance free but will degrade over time and require replacement.

Plain and laminated neoprene elastomeric bearings are manufactured by pretread.com both in neoprene and natural rubber compounds confirming to AASHTO/ BS/EN /DIN standards. Bridge bearings and bridge bearing pads are manufactured in neoprene rubber compounds,.. unless otherwise specified for natural rubber compound. Our specialization is always in neoprene compound and bridge bearings, elastomeric, pads, high damping neoprene rubber bearings are manufactured from our years of experience, and with support from our technical partners for all requirements of neoprene bridge bearing, neoprene bridge bearings rubber bearing, steel bearing, pot bearing, guided bearing, for all bridge and building bearing applications.

Elastomeric bridge bearing are a must in modern bridge building. bridge bearings include neoprene bearing pads, neoprene bridge bearings, laminated elastomeric bearings seismic isolators referred bridge bearing pads in construction industry. Neoprene laminated bridge bearings designed manufactured based standards specifications British Standard, AASHTO, and European Norms En 1337.[1] Internal structure consists sandwich of mild steel shims neoprene rubber moulded one unit. Elastomeric bearing pads compress on vertical load accommodate horizontal rotation provide lateral shear movement. Elastomeric bearing pads most economical solution for construction of large span bridges and buildings.

We manufacture elastomeric bearings in our plant with high-grade virgin Neoprene - elastomer- meeting AASHTO M 251 EN 1337-3-2005 Specification.

Why use neoprene laminated elastomeric rubber bearings or steel pot bearings for Bridges and buildings ?

A bridge basically consists of bridge deck supported by piers. In order to avoid damage by movements due to thermal expansion, vehicular movement, loading to piers, neoprene bridge bearings are used to accommodate these movements so as to reduce reaction forces and bending movement to within safety limits of structure. Neoprene as well as Natural Rubber is an ideal engineering polymer material for bridge bearings as it is highly elastic and sufficiently soft to accommodate these movements without transmitting harmful stress and also it absorbs and isolates energy from impacts and vibrations. Neoprene Bridge bearings are devices for transferring loads and movements from deck to piers.

Pretread.com with our manufacturing facility in United Arab Emirates is direct manufacturer of Laminated Neoprene Bridge Bearings and Laminate Elastomeric Bearings, ptfe Teflon sliding bearings Steel Pot bearings , Guided Bearings , Fixed Pot bearings, Temporary Sliding bearings etc. We at pretread.com, from our manufacturing facility in United Arab Emirates manufacture neoprene bridge bearings, elastomeric, pads, high damping rubber bearing, rubber expansion joints, PTFE sliding bearing, sliding bearings to AASHTO / BS / DIN/ EN specifications for the first time in the Middle East U.A.E. form 1999. Laminated elastomeric bearings, bridge bearings, bridge bearing pads high damping bearing pads steel pot bearings, spherical bearings guided bearings are manufactured mostly in neoprene elastomeric compounds, confirming to AASHTO/ BS/EN /DIN specifications.

Laminated Bearing designing.

Our technical and design team can design right type of bearing based on loads provided design cbearing for end applications. On receipt of corbel size, load and movement details of requirements, calculations and bearings sizes can be provided based on results on parameters compared to AASHTO LRFD - and EN 1337-3-2005.

.

Advantages of Neoprene Elastomeric bearings.

Neoprene bridge bearings - plain or laminated - elastomeric bearings are much easier to install in a bridge compared to other types of bearings require nil maintenance. Unlike most other elastomer, Neoprene rubber under-goes no marked stiffening at low temperature when the thermal contraction of the bridge deck is at maximum. Correctly-designed and suitably-compounded laminated Neoprene Rubber bridge bearings can be confidently expected to function efficiently for at least a decade.

As efficient bearing plates for pre-cast, pre-stressed concrete or steel beams in bridges and buildings, Neoprene Pads - plain and laminated –designed manufactured by us permits smooth uniform transfer of load from the beam to substructure allowing beam rotation of bearing due to deflection of beam under load. Bridge bearings further allow lateral and longitudinal movement of beam caused by thermal forces. Neoprene Pads have no movable parts and thermal expansion and contraction are absorbed by the pad's ability to give and take in shear. There is no sliding motion between pad and beam or between pad and abutment.

Bearing Load Calculations

Let us verify load calculations for your bearings. Send us load details in bearing schedule will design the right bearings for end applications.

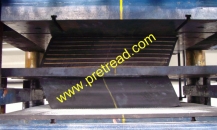

Manufacturing procedure neoprene laminated elastomeric bearings- Compression moulding:

Elastomeric bearings are composed of multiple laminate of elastomeric material separated by steel reinforcing. Overall size of bearing, number of laminate thickness of laminate designed in accordance to requirement of Load to be Transferred. Bearings having steel plates as reinforcement shall be cast/compression moulded/vulcanized as a single unit in a mould under pressure and heat. A plain elastomeric bearing pad and steel load distribution plate combination shall be classified as a laminated elastomeric bearing.

Internal Laminate

Internal plates shall be ASTM A 36/A 36M or A 570/A 570M, Grade 36 or Grade 40. All plates shall be deburred. Steel plates separating elastomeric layers will be completely bonded by vulcanization to elastomeric material on all surfaces using special metal to rubber bonding adhesive. All external load bearing steel plate(s) if present, shall be factory vulcanized to elastomeric bearings during primary molding process.

Different types of Laminated Elastomeric bearings.

Tapered bearings are provided to work with inclinations in super structure. The taper is accomplished by using a tapered steel plate (Fig. 1), or for slight tapers, by tapering the elastomer layers. Special loadings are met by inclined mounting of bearings.

A particularly common variation is shown in Fig. 2. This hybrid Elastomeric/Sliding Bearing provides a stainless-steel-on-PTFE slip plane on top of a conventional Elastomeric Bearing. Daily movements are taken within the elastomer; greater movements cause greater shear force in the elastomer, which overcomes the friction at the PTFE/stainless steel interface thereby accommodating these greater, less frequent movements through sliding.

Customized ancillary plates or “Load” plates are vulcanize-bonded to bearings to provide specialized mounting and anchoring systems (See Figs. A through C). They can be shaped and/or drilled to most requirements. If they are to be welded in place, they must be detailed to mitigate excessive heat transfer to elastomer.

Testing of Neoprene Bridge Bearings

In house Quick Production Test of all bearings shall be done at Clients/Representative presence. Tests confirming to AASHTO specification in accordance with Acceptance Testing on either Level I or Level II or Short/Long-Duration Compression Test up to 10000 kN with horizontal shear up to 600kN can be carried out in our facility. Test specimens shall be in accordance with ASTM D 3182 or D 3183. Where test specimens are cut from finished product, a 20 percent variation from the original physical properties is allowed. 3rd party witnessing of these tests are also done in our facility as there are no independent laboratory in middle east with such capabilities.

Laminated elastomeric bearings with Natural Rubber.

Natural Rubber Compounds are also used where Laminated Elastomeric bearings are to be designed, manufactured and tested in accordance to requirements in.

Please browse through our web site for more information and contact us for further details and inquires for neoprene bridge bearings,bridge bearing, bearing pads,seismic isolators, laminated elastomeric bearings, precure tread rubber, retread equipments, moulded rubber products molded rubber,rubber products manaufactured in Middle east UAE dubai RAK.

Pretread.com, a reliable source for bridge bearing, neoprene bridge bearing , elastomeric bearings, ptfe teflon sliding bearings, steel pot bearing, mechanical steel bridge bearings sliding bearing ptfe Teflon pipe supports, is established from 1999 with ISO certifications in United Arab Emirates UAE Dubai with three manufacturing facility, offers bridge and structural bearings for buildings and bridges, and these bearings are manufacture in UAE which means all your requirement for bridge and structure constructions bearing system can get manufactured from pretread.com UAE Dubai ras al Khaima. Kindly contact us with your requirements

![]() Products

Products ![]() Bridge Bearings

Bridge Bearings ![]() Laminated elastomeric bridge bearings

Laminated elastomeric bridge bearings