Home ![]() Services

Services ![]() Failed bearings and expansion joints

Failed bearings and expansion joints

Failed bearings and expansion joints

( How Polymet can be of help get out of the mess)

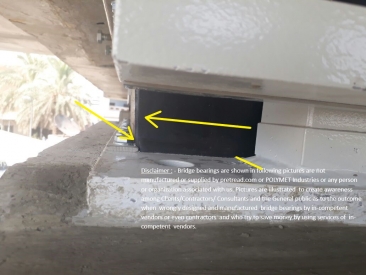

Disclaimer : - Bridge bearings are shown in following pictures are not manufactured or supplied by pretread.com or POLYMET Industries or any person or organization associated with us. Pictures are illustrated to create awareness among Clients/Contractors/ Consultants and the General public as to the outcome when wrongly designed and manufactured bridge bearings by in-competent vendors or even contractors and who try to save money by using services of in-competent vendors.

Elastomeric bearings, Steel Pot and spherical bearings and bearing pads are used in bridges and concrete buildings to support large vertical loads, lateral shear, and rotations of these structures by accommodating loads and movements due to thermal expansions, relaxations, creep, and rotations. The design criteria for these bearings are stringent engineering and are frequently not understood and followed. We here show a few examples of the failure of elastomeric bearings. These can be due to assessment errors of loads, shear and rotation, incompetent design capabilities, design errors and issues, and errors in manufacturing practices and maintenances, all of which lead to premature failure as well as earlier failure of bearings, including yield and rupture of internal reinforcement elastomeric layers, exposed steel shims,delamination of reinforcement, cracking or tearing of the rubber, fatigue, and instability, dislocation from bearing base, generates whats called " bearing walking".

.jpg)

The importance of the usage of FMEA to evaluate possible failures and prevent by correcting t proactively rather than reacting to adverse and costly events after failures are reported during defect liability and warranty period. Prevention will always reduce the risk of expensive replacements including total replacement of newly designed and manufactured bearings. The careful design followed by prototyping, extensive load/shear/rotation testing to be done prior to final bearing type and size determination, then follow up manufacturing with proven experience in the process. Experimental results will be summarized, and the influences of different manufacturing techniques from rich experience are illustrated to provide a high-quality sustainable bridge bearings and expansion joints. Few pictures here are showing the outcome when bridge bearings are designed and manufactured and supplied by inexperienced vendors or even a few builders who try to cut corners to save pennies. Bridges and buildings have to be built with sustainability and social obligation to protect human life on and around these structures during and aftermath of a seismic reaction in the region.

.jpg)

Premature and service failure of road expansion joints between girders in bridges are a big concern for contractors and bridge owners. It is noticed that many bridges experience frequent damage in expansion joints, soon after opening to traffic and the problems remain unsolved even after replacement with new expansion joints. Criteria in choosing of expansion joint have to be based on expansion gap, both at expansion and contraction of girders and movements of the bridge and deformation of the girders, the climate of the region ( sun, rain, snow)and vehicular axial loads, and speed. For Middle East roads, the following criteria are best suited.

All steel reinforced rubber expansion joints offered by POLYMET will be manufactured with high content of UV protection polymer, giving a smoother ride at high speeds for vehicles, rubber does not expose steel, which is the reinforcement, for high axial loads and stability. The loads exerted per axel when stationary and at different speeds are different. In slow-moving traffic, the load exerted on an expansion joint can be 10 tons per axle per vehicle.

Choosing the right kind of expansion joint is the only first step, installing them properly and periodical inspection and preventive maintenance come the next step pretread.com POLYMET will be glad to assist you and please contact us immediately.

Thank you